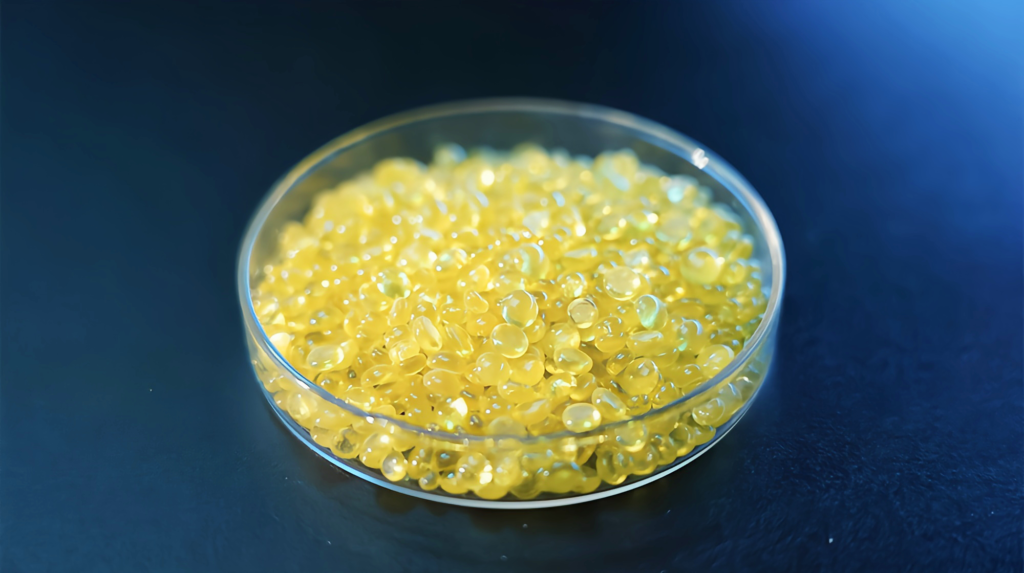

resin

Ⅰ. Enhance The Durability And Adaptability

The introduction of resins makes paint coatings more resistant to abrasion and better able to withstand external environmental aggression, such as reducing the chances of water vapor infiltration or acid and alkali erosion and other problems, thereby improving service life. At the same time, due to the variety of resins and the flexibility of choice, customized adjustments can be made according to the actual needs, optimizing the formulation design to achieve the best results, to meet the customer’s specific scenarios of application needs, such as building exterior wall decoration protection, automotive surface rust treatment, and so on.

II. Enhancement Of Performance Indicators

Different types of resins, such as acrylic resins, epoxy resins, polyester resins and polyurethane resins, have their own characteristics in terms of physicochemical and mechanical properties. They determine the toughness of the final product, the strength of adhesion to the substrate material, as well as anti-corrosion and weather resistance and other important parameters of the performance level. High-quality stable resin can also ensure that the paint and coating in the storage period does not occur significant physical and chemical changes, thus ensuring good product quality stability.

Ⅲ. Film-forming And Curing

Resin, as the main film-forming substance of paint coatings, has the ability to combine pigments, fillers, etc. together. It can form a uniform and dense coating film on the substrate, and further enhance its stability and performance through the curing process. This characteristic makes the resin an indispensable basic ingredient in paints and coatings.

To summarize, resins not only play a basic role in film formation and curing in paint coatings, but also provide a strong guarantee for the overall performance and application effect of paint coatings by improving performance indexes and enhancing durability and adaptability.